Comprehensive Guide to Understanding PCB Circuit Applications and Trends in 2023

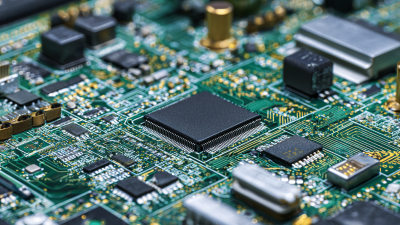

In 2023, the landscape of electronics is increasingly shaped by advancements in PCB circuit technology, reflecting a significant evolution in their applications across various industries. According to a recent report by Fortune Business Insights, the global PCB market is expected to grow from $71.15 billion in 2021 to $98.44 billion by 2028, driven by the increasing demand for smart devices, automotive electronics, and IoT applications. This surge underscores the importance of understanding the latest trends and innovations in PCB circuits, as they play a crucial role in enabling complex electronic systems and enhancing overall performance. With a focus on key applications ranging from consumer electronics to industrial automation, this comprehensive guide aims to provide insights into the current state of PCB circuit technology and its future trajectory, offering a valuable resource for professionals and enthusiasts alike.

Emerging PCB Applications in Consumer Electronics for 2023

In 2023, the field of consumer electronics is witnessing a significant evolution, largely driven by advancements in PCB (Printed Circuit Board) technology. With the global PCB market projected to reach $85 billion by 2027, according to industry reports, applications in consumer electronics are emerging at an unprecedented pace. This growth is fueled by the rising demand for smart devices, wearables, and IoT (Internet of Things) applications, which require compact and highly efficient circuit solutions.

One notable trend is the integration of flexible PCBs in consumer electronics. These adaptable circuit boards enable the design of ultra-thin and lightweight gadgets, making them an ideal choice for wearables and smartphones. A recent survey indicated that the flexible PCB sector alone is expected to grow at a CAGR of 12% through 2023, largely driven by improvements in material science and manufacturing technologies. Furthermore, the increased emphasis on sustainability is prompting manufacturers to adopt eco-friendly PCB designs, aligning with consumer preferences for greener products without compromising performance.

As consumer electronics continue to evolve, the role of advanced PCB applications is becoming increasingly critical. Enhanced features like wireless charging, higher processing power, and improved signal integrity are now achievable through innovative PCB designs. Industry insiders predict that as technologies like 5G and AI become ubiquitous, PCBs will play a pivotal role in enabling the next generation of smart devices, firmly establishing their importance in shaping the future of consumer electronics.

Emerging PCB Applications in Consumer Electronics for 2023

Innovative Trends in PCB Design: Sustainability and Miniaturization

In 2023, the PCB design landscape is witnessing a significant shift towards sustainability and miniaturization. Reports indicate that the global PCB market is projected to reach approximately $80 billion by the end of the year, with sustainable practices becoming a pivotal trend. Manufacturers are increasingly adopting eco-friendly materials and processes to meet the demands of environmentally conscious consumers while also complying with stricter regulations. For instance, the use of bio-based resins and lead-free soldering techniques has gained traction, significantly reducing the environmental impact of PCB production.

Tips: When designing PCBs with sustainability in mind, consider incorporating recyclable materials and optimizing layouts to reduce waste during manufacturing. This not only helps the environment but also appeals to a growing market for green technology.

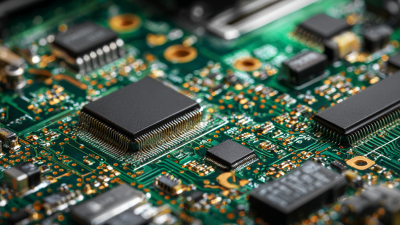

Miniaturization continues to push the boundaries of PCB design, with advancements in electronic components allowing for smaller, more powerful devices. According to industry analysts, the trend towards smaller PCBs is driven by the proliferation of IoT devices and wearables, which require high-density interconnect technology. As a result, design engineers must focus on developing compact, efficient layouts that maintain signal integrity while accommodating complex functionalities.

Tips: To achieve miniaturized PCB designs, leverage advanced simulation software to optimize your layouts and ensure that components are placed efficiently without compromising performance.

Critical Role of PCBs in IoT Devices: Connecting the Future

The proliferation of the Internet of Things (IoT) devices has underscored the critical role of Printed Circuit Boards (PCBs) in modern technology. As reported by MarketsandMarkets, the global IoT market is expected to reach $1.1 trillion by 2026, doubling from 2021. This growth trend emphasizes the need for robust and reliable PCBs that can support the myriad of applications, from smart home devices to industrial sensors. With IoT devices becoming increasingly interconnected, the integration of advanced PCB technologies—such as flexible circuits and multilayer boards—has become essential in meeting performance requirements while minimizing energy consumption.

When designing PCBs for IoT applications, it is vital to consider size, weight, and durability. Here are a couple of tips to guide your PCB design process: First, prioritize the selection of materials that offer excellent thermal conductivity and impedance controlled features, which are crucial for maintaining signal integrity in densely packed circuits. Second, implement design for manufacturing (DFM) principles early in the design stage to streamline production processes and reduce time-to-market. By adhering to these practices, designers can create highly efficient PCBs that not only meet current demands but also anticipate future technological advancements in the IoT landscape.

Comprehensive Guide to Understanding PCB Circuit Applications and Trends in 2023 - Critical Role of PCBs in IoT Devices: Connecting the Future

| Application Area | Trends in 2023 | Key Features | Market Growth (%) |

|---|---|---|---|

| Consumer Electronics | Smart integration, Miniaturization | Flexible PCBs, Multi-layer designs | 8% |

| Industrial Automation | Increased connectivity, Smart sensors | Robust design, High thermal performance | 10% |

| Healthcare Devices | Telehealth expansion, Wearable tech | Biocompatible materials, Wireless charging | 12% |

| Telecommunications | 5G technology, Enhanced data processing | High-frequency design, Compact size | 15% |

| Automotive Industry | Autonomous driving, Electric vehicles | High reliability, Advanced thermal management | 9% |

Challenges and Solutions in PCB Manufacturing for 2023

The PCB manufacturing industry faces several challenges in 2023, largely driven by the increasing complexities of circuit designs and the demand for high-density interconnects. As electronics continue to permeate every facet of life—from consumer gadgets to industrial machinery—the need for smaller, more efficient PCBs becomes critical. However, traditional manufacturing processes often struggle to keep up with these advancements, leading to issues such as production delays, increased costs, and difficulties in maintaining quality standards.

To address these challenges, manufacturers are turning to automation and advanced materials. Incorporating AI and machine learning into production lines can enhance monitoring and quality control, ensuring that defects are minimized and production efficiency is maximized. Moreover, the use of new materials, such as flexible and high-frequency laminates, is becoming more common, allowing for designs that cater to the evolving technological landscape. By embracing these innovative solutions, the PCB industry can not only overcome existing hurdles but also position itself to meet future demands more effectively.

Future-Proofing Your PCB Designs: Best Practices and Strategies

In 2023, future-proofing PCB designs becomes imperative as the electronics industry rapidly evolves. Advances in technology, including the rise of AI and IoT, demand that PCB designs not only meet current specifications but also anticipate future requirements. A recent McKinsey report highlights the significance of adaptable operating models that allow organizations to stay agile in a fast-moving environment, suggesting that similar strategies should be applied in PCB design. Engineers are encouraged to implement modular designs that facilitate upgrades and integration of new technologies without complete redesigns.

Moreover, sustainable design principles are making waves in PCB manufacturing. The focus on eco-friendly practices not only aligns with global environmental standards but also resonates with increasingly discerning consumers. Incorporating sustainable materials can result in cost efficiencies over time, as highlighted in various industry reports. By prioritizing sustainability and modularity, PCB designers ensure that their products meet both current and future market demands while maintaining a competitive edge in a rapidly changing landscape.

Related Posts

-

Innovative Uses in Aerospace and Challenges in Best Circuit Board Fabrication

-

Leading the Way: Unmatched Export Strength of China’s Top PCB Circuit Boards

-

Innovative Circuit Board Assembly Techniques Shaping the Future of Electronics

-

Unlocking Success: The Advantages of Advanced PCB Fabrication Techniques for Global Buyers

-

Exploring Unique Alternatives to Flexible PCB Board Solutions

-

15 Essential Tips for Efficient Printed Circuit Board Assembly