Innovative Uses in Aerospace and Challenges in Best Circuit Board Fabrication

The aerospace industry is experiencing unprecedented advancements, with innovative technologies driving the demand for sophisticated components, particularly in circuit board fabrication. According to a report by Markets and Markets, the global aerospace circuit board market is projected to grow from $2.2 billion in 2022 to $3.4 billion by 2027, reflecting an impressive CAGR of 9.1%. However, as the complexity of aerospace applications increases, so do the challenges associated with best practices in circuit board fabrication. These challenges include ensuring reliability and performance under extreme environmental conditions, meeting stringent regulatory requirements, and managing supply chain intricacies. This blog will explore various innovative uses of circuit boards in aerospace while also addressing the pressing fabrication challenges that industry players face today.

Innovative Technologies Shaping the Future of Aerospace Engineering

Innovative technologies are revolutionizing the field of aerospace engineering, enabling engineers to design lighter, more efficient, and highly functional aircraft. One key development is the integration of advanced composite materials, which significantly reduce weight while maintaining structural integrity. These materials not only enhance fuel efficiency but also improve overall performance and longevity of aerospace components. Additionally, additive manufacturing, commonly known as 3D printing, is being harnessed to create intricate parts that traditional manufacturing techniques cannot achieve. This flexibility allows for faster prototyping and customized solutions tailored to specific mission requirements.

Another exciting trend is the incorporation of artificial intelligence and machine learning into the aerospace sector. These technologies streamline design processes, optimize flight operations, and even enhance predictive maintenance capabilities. By analyzing vast amounts of data, AI can identify potential issues before they become critical, leading to increased safety and reduced downtime. Furthermore, developments in avionics and communication technology facilitate improved navigation systems, allowing for safer and more efficient air travel. Collectively, these innovations are not only shaping the future of aerospace engineering but also addressing the industry's ongoing challenges in sustainability and efficiency.

Key Challenges in Circuit Board Fabrication for Aerospace Applications

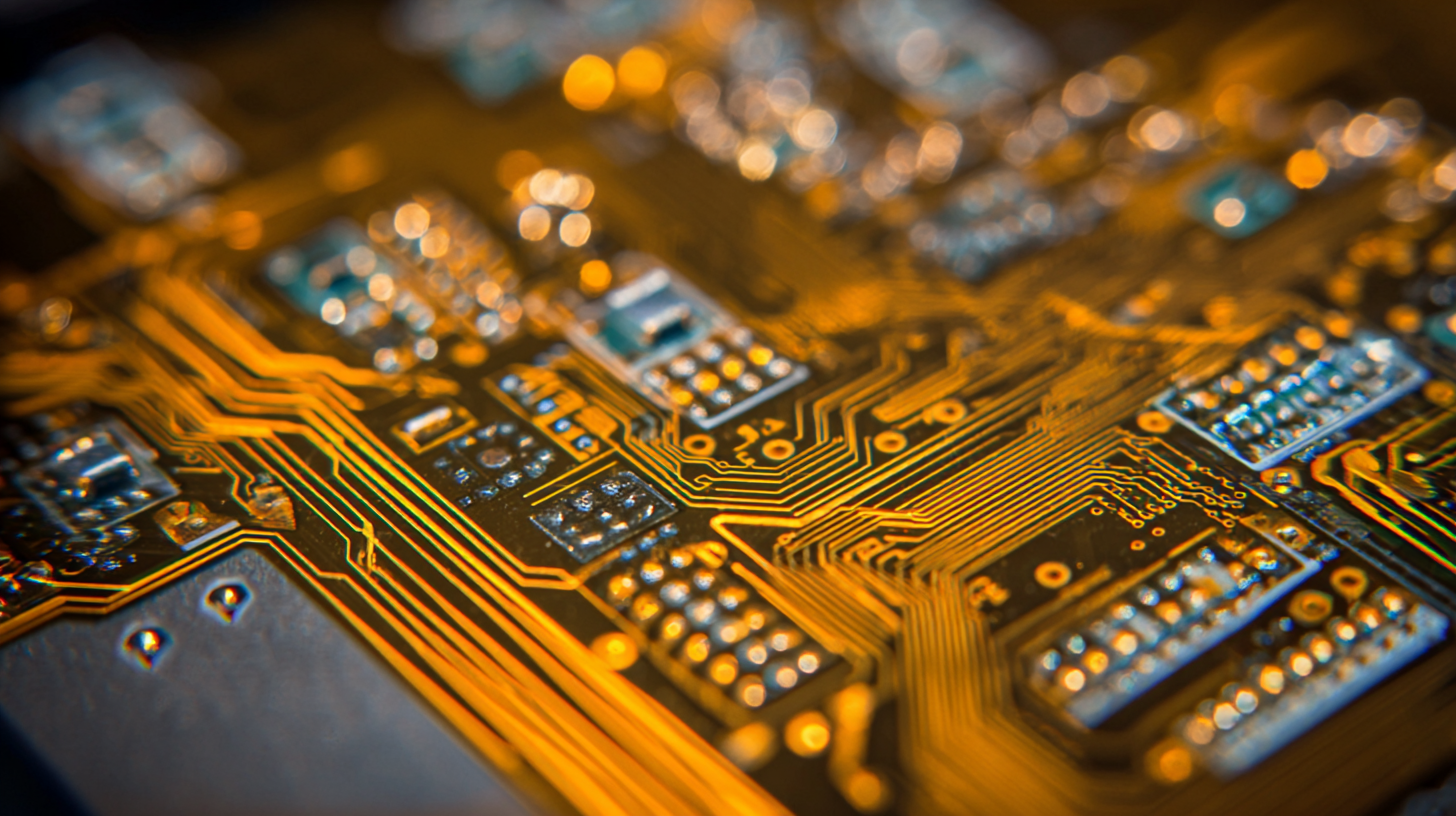

The aerospace industry is increasingly relying on advanced circuit board fabrication to meet the stringent demands of modern aircraft and spacecraft. However, the uniqueness of aerospace applications brings several key challenges in the fabrication process. One major challenge is the requirement for lightweight yet durable materials. Aerospace circuit boards must endure extreme conditions, including high temperatures, pressure variations, and radiation, necessitating innovative materials that can maintain performance without significantly adding weight.

Additionally, precision is critical in aerospace applications, where even the slightest failure can lead to catastrophic outcomes. This precision demands advanced manufacturing techniques and quality control processes that can be both time-consuming and costly. Furthermore, the integration of microelectronics in circuit boards requires a keen focus on miniaturization and efficiency, pushing manufacturers to develop new methods to ensure that components are not only functional but also optimized for space constraints.

As the demand for more sophisticated and reliable systems in aerospace continues to grow, addressing these challenges in circuit board fabrication will be essential for the future of the industry.

Emerging Trends in Circuit Board Materials and Their Impact on Aerospace

The aerospace industry is witnessing rapid advancements in circuit board materials, which are crucial for enhancing the performance and reliability of aircraft systems. Emerging trends highlight the use of lightweight composites and advanced polymers that can withstand extreme temperatures and pressure variations. These innovations not only reduce the overall weight of the aircraft but also improve fuel efficiency—a critical factor in modern aerospace design.

Moreover, the integration of flexible circuit boards is becoming increasingly popular in aerospace applications. These boards provide designers with the flexibility needed to fit intricate designs into compact spaces onboard aircraft. Their ability to withstand mechanical stress while maintaining performance makes them ideal for various aerospace systems, including avionics and sensors. However, manufacturers face challenges in maintaining quality and consistency during fabrication, as the complexity of these materials often leads to increased production costs and a higher potential for defects. Balancing innovation with effective fabrication processes will be key to overcoming these hurdles and fully harnessing the benefits of new circuit board technologies in the aerospace sector.

Best Practices for Ensuring Quality and Reliability in Electronics Manufacturing

In the rapidly evolving aerospace sector, ensuring quality and reliability in electronics manufacturing is paramount. One of the best practices involves the rigorous selection of materials. High-performance materials that can withstand extreme temperatures and atmospheric pressures are essential for circuit boards in aerospace applications. Additionally, using advanced simulation software during the design phase can help identify potential failure points, thus ensuring that the final products meet stringent industry standards.

Another critical aspect is the implementation of robust testing protocols. This includes thorough inspection methods such as Automated Optical Inspection (AOI) and X-ray analysis to detect any defects early in the manufacturing process. Emphasizing a comprehensive testing regime not only helps in identifying issues but also in validating the overall performance of circuit boards under real-life conditions. Furthermore, regular training for manufacturing staff on the latest technologies and best practices can enhance the skill set that supports quality assurance efforts, ultimately leading to more reliable electronics in aerospace applications.

Innovative Uses in Aerospace and Challenges in Circuit Board Fabrication

Strategic Approaches to Overcome Challenges in Aerospace Circuit Board Production

The aerospace industry demands precision and reliability, placing immense pressure on circuit board fabrication. To overcome the inherent challenges, manufacturers must adopt strategic approaches that prioritize quality and efficiency. One key strategy involves the integration of advanced materials that enhance thermal stability and mechanical strength. This not only improves the durability of circuit boards under extreme conditions but also reduces the overall weight, which is critical for aerospace applications.

Moreover, investing in automation and advanced manufacturing technologies can significantly streamline production processes. Implementing automated inspection systems ensures consistency and accuracy, minimizing the risk of defects. Additionally, utilizing data analytics allows manufacturers to optimize their workflows, predict failures, and enhance decision-making. Collaboration with research institutions can foster innovation, leading to the development of next-generation circuit boards that meet the unique demands of the aerospace sector.

By embracing these strategic approaches, the industry can effectively address fabrication challenges and pave the way for more innovative and reliable aerospace solutions.