Addressing Common Challenges in Sourcing the Best PCB Circuits for Global Buyers

In the competitive landscape of electronics manufacturing, sourcing high-quality PCB circuits is a formidable challenge that global buyers face. A recent study by the IPC (Association Connecting Electronics Industries) highlighted that nearly 60% of companies encountered difficulties in finding reliable suppliers for printed circuit boards, leading to increased production timelines and costs. Additionally, as the demand for complex, multi-layered PCB circuits continues to rise, manufacturers must navigate not only the intricacies of the technology but also the critical aspects of after-sales service and maintenance costs. Effective management of these factors is essential for maintaining a competitive edge in the market. By understanding the common challenges in sourcing PCB circuits and examining successful case studies from industry leaders, buyers can make informed decisions that enhance their operational efficiency and reduce total lifecycle costs.

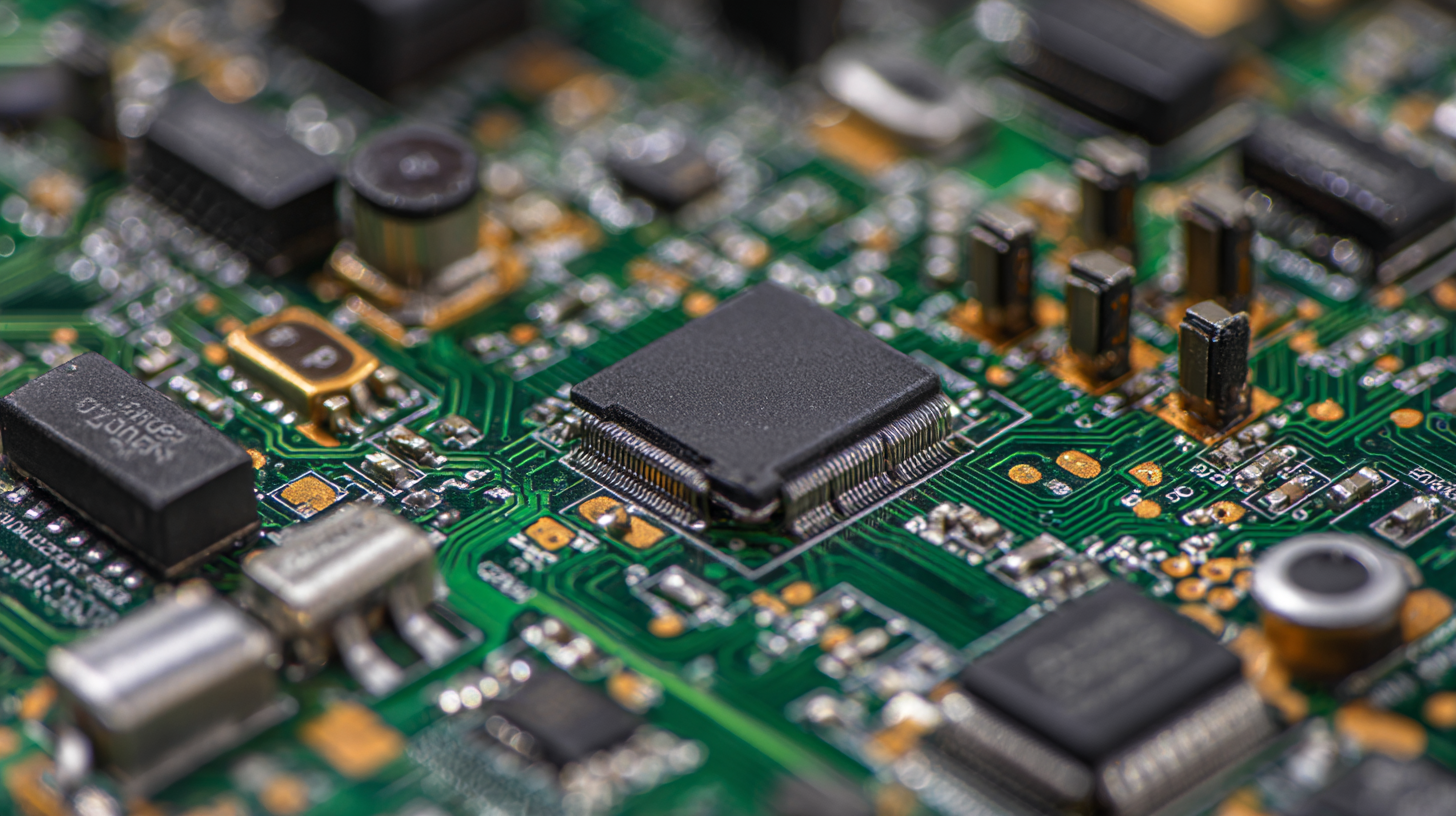

Understanding the Distinct Characteristics of Various PCB Types for Global Sourcing

When sourcing PCB circuits globally, understanding the distinct characteristics of various PCB types is crucial for making informed decisions. Different PCB types such as single-sided, double-sided, and multilayer boards serve unique purposes and come with varying manufacturing complexities and costs. For instance, single-sided PCBs are less expensive and easier to produce, making them ideal for simple electronic devices. On the other hand, multilayer PCBs, which can accommodate more complex circuits, are essential for high-performance applications, albeit at a higher cost.

Tips: When evaluating PCB options, consider the specific requirements of your project, including size, complexity, and environmental factors. Additionally, engage with manufacturers to clarify any ambiguities about the materials and technologies used in their PCB production, ensuring they meet your standards.

Another important aspect to consider is the compliance with international standards. Different regions may have varying regulatory requirements for electronic components, so it's essential to ensure that the PCBs sourced comply with local and global certifications. This not only guarantees product quality but also prevents potential bottlenecks during customs clearance.

Tips: Stay updated on the latest industry regulations and standards to avoid disruptions in your supply chain. Collaborating with trusted suppliers who have a solid track record in compliance can significantly mitigate risks associated with sourcing PCBs for your global needs.

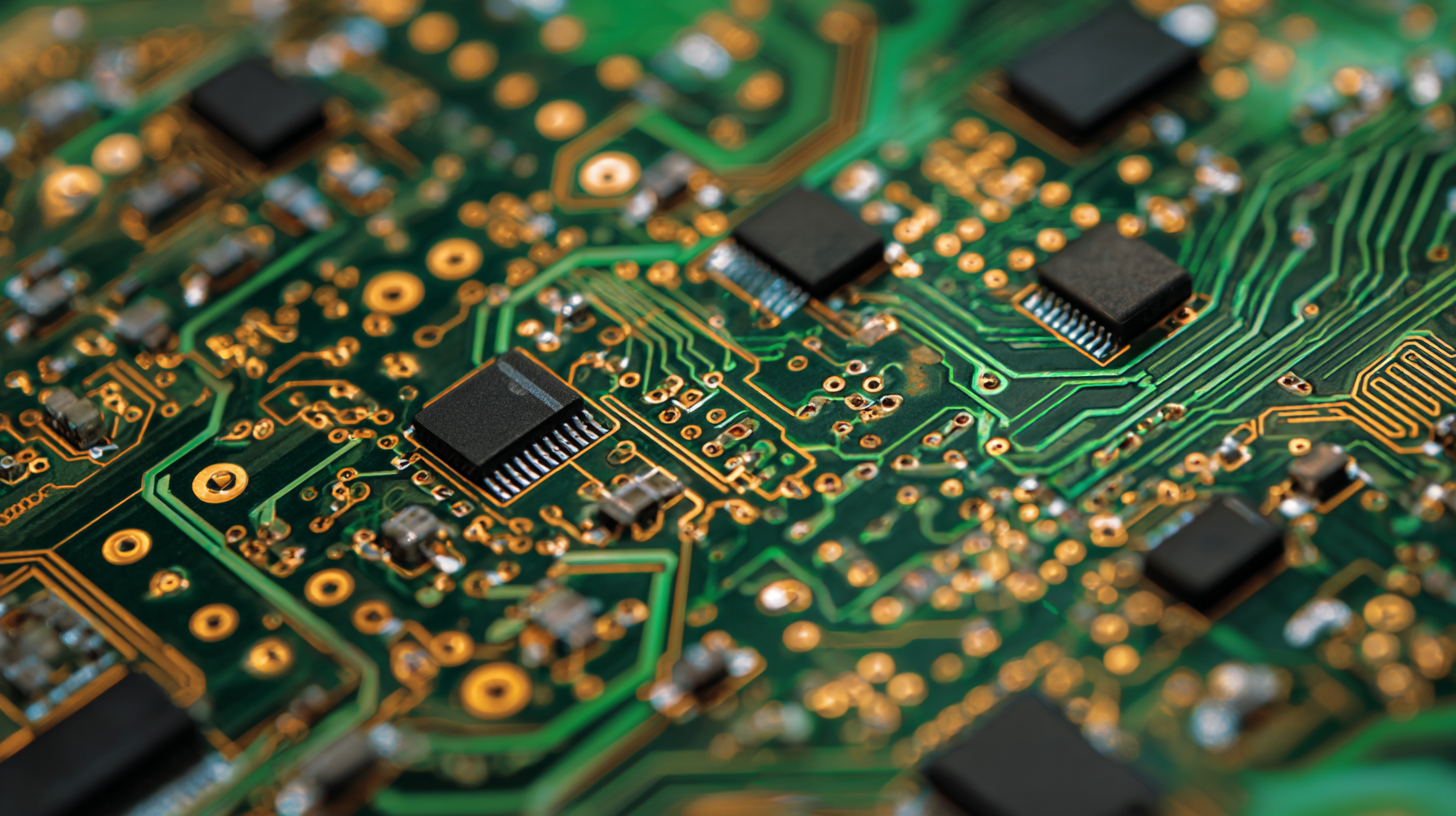

Identifying Key Application Areas for Rigid, Flexible, and Rigid-Flex PCBs in Industry

In the evolving landscape of printed circuit boards (PCBs), understanding the application areas for rigid, flexible, and rigid-flex designs is vital for global buyers. A recent report highlights that the Substrate-Like PCB market is projected to reach USD 7.41 billion by 2034, growing at a compound annual growth rate (CAGR) of 6.13% during the forecast period. This growth is indicative of the increasing demand across various sectors, including telecommunications, consumer electronics, and automotive, particularly as the industry adapts to new technology trends.

The flexible PCB market is poised for recovery in 2024, thanks to the rising demand from new devices and electric vehicles. This market is expected to significantly influence product strategies, given that flexible PCBs offer remarkable characteristics such as thinness, high tensile strength, and unmatched flexibility. Furthermore, the Rigid-Flex PCB market is also gaining traction, with analyses predicting substantial growth between 2024 and 2032. Such versatility in PCB types not only supports emerging technologies but also allows manufacturers to innovate and design next-generation electronics efficiently, solidifying their importance in both traditional and advanced applications.

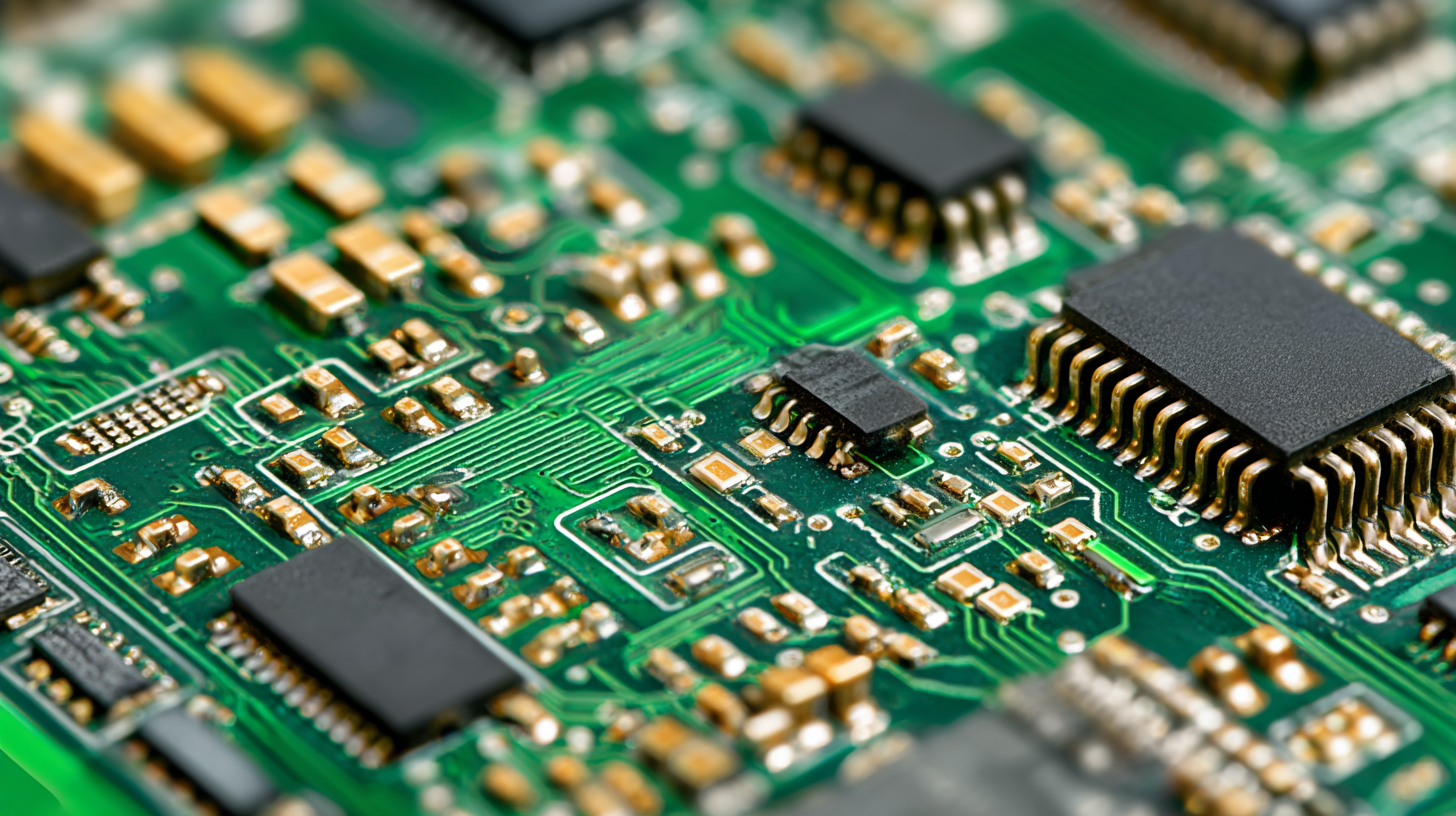

Evaluating Quality Standards and Testing Protocols for PCBs in International Markets

In the rapidly evolving world of electronics, the importance of stringent quality standards and rigorous testing protocols for printed circuit boards (PCBs) cannot be overstated. According to a 2023 report from the IPC (Association Connecting Electronics Industries), up to 30% of PCBs fail quality tests at some stage of production, leading to significant financial losses for manufacturers and distributors. Global buyers must carefully evaluate these quality metrics to ensure reliability and performance in their products, especially when sourcing from different international markets.

To address these challenges, international buyers are encouraged to familiarize themselves with specific certifications and testing practices, such as ISO 9001 and IPC-A-610. These standards establish a framework for consistent quality management and set expectations for the acceptable quality levels of PCBs. Furthermore, the introduction of automated optical inspection (AOI) and X-ray inspection techniques has become vital in identifying defects that manual inspections might overlook. Reports indicate that companies implementing these advanced testing protocols have seen a reduction in defect rates by up to 40%, ultimately enhancing customer satisfaction and operational efficiency.

As the global demand for high-quality PCBs continues to rise, understanding and implementing robust quality assurance practices is essential for competitive success.

Analyzing Cost Effectiveness and Supply Chain Dynamics in PCB Sourcing Strategies

When sourcing PCB circuits, global buyers must navigate complex supply chain dynamics and cost-effectiveness strategies. Understanding the implications of international freight, tariffs, and local regulations can significantly impact the overall budget. To optimize expenditures, buyers should consider establishing partnerships with local manufacturers. This local approach can mitigate shipping costs and lead to a more responsive supply chain.

**Tip:** Always conduct a thorough analysis of the total landed cost, which includes manufacturing, shipping, tariffs, and potential duties. By consolidating shipments or choosing suppliers with established logistics, buyers can further reduce costs.

In addition to cost considerations, effective communication with suppliers is crucial. Clear dialogues about lead times, production capabilities, and quality standards help ensure that both parties align expectations. Utilizing technology and software for real-time tracking can enhance transparency within the supply chain.

**Tip:** Build a strong relationship with suppliers through regular feedback. This not only assures quality but also opens avenues for negotiating better prices and terms, particularly with larger orders or long-term contracts.

Cost Effectiveness in PCB Sourcing Strategies

This chart illustrates the cost effectiveness of various PCB sourcing strategies based on factors such as material costs, manufacturing costs, and shipping expenses. It provides insights into the financial considerations crucial for global buyers.

Exploring Emerging Trends in PCB Technology and Their Impact on Global Manufacturing

In the evolving landscape of PCB technology, several emerging trends are reshaping global manufacturing practices. One significant advancement is the integration of automation and AI into the PCB manufacturing process. These technologies enhance precision and efficiency, reducing errors and accelerating production timelines. As manufacturers adapt to these innovations, they can meet the increasing demands for higher quality and quicker turnarounds, a necessity in today's fast-paced market.

Another trend gaining traction is the shift towards sustainable and eco-friendly materials in PCB production. With growing environmental concerns, companies are exploring biodegradable substrates and lead-free soldering processes. This not only addresses regulatory pressures but also aligns with consumers' preferences for environmentally responsible products. As sustainability becomes a competitive advantage, global buyers are increasingly seeking suppliers who prioritize green practices alongside technological excellence.

Additionally, the rise of IoT devices is pushing the development of more complex and compact PCBs. This trend requires manufacturers to adopt advanced design tools and materials that can accommodate intricate circuitry and high-density configurations. By staying ahead of these trends, businesses can enhance their product offerings and ensure they remain relevant in a rapidly changing global marketplace.

Addressing Common Challenges in Sourcing the Best PCB Circuits for Global Buyers - Exploring Emerging Trends in PCB Technology and Their Impact on Global Manufacturing

| Trend | Impact on Manufacturing | Challenges Faced | Solutions |

|---|---|---|---|

| Deep Learning and AI | Enhanced design capabilities and predictive maintenance | Integration complexity and reliance on data quality | Invest in data purification and AI training |

| Flexible PCBs | Increased application in wearable tech and compact devices | Higher production costs and design limitations | Optimize supply chain and technology advancements |

| Sustainable Materials | Reduction in environmental impact | Limited availability and performance issues | Collaborate with suppliers for better material access |

| Automation in Production | Increased efficiency and reduced labor costs | Initial investment and workforce adaptation | Provide training programs for workforce |

| 5G Technology | New opportunities for high-speed connections | Design complexities and compatibility | Invest in R&D for advanced design capabilities |