Ultimate Guide to Choosing the Best Flexible Printed Circuit Board for Your Project

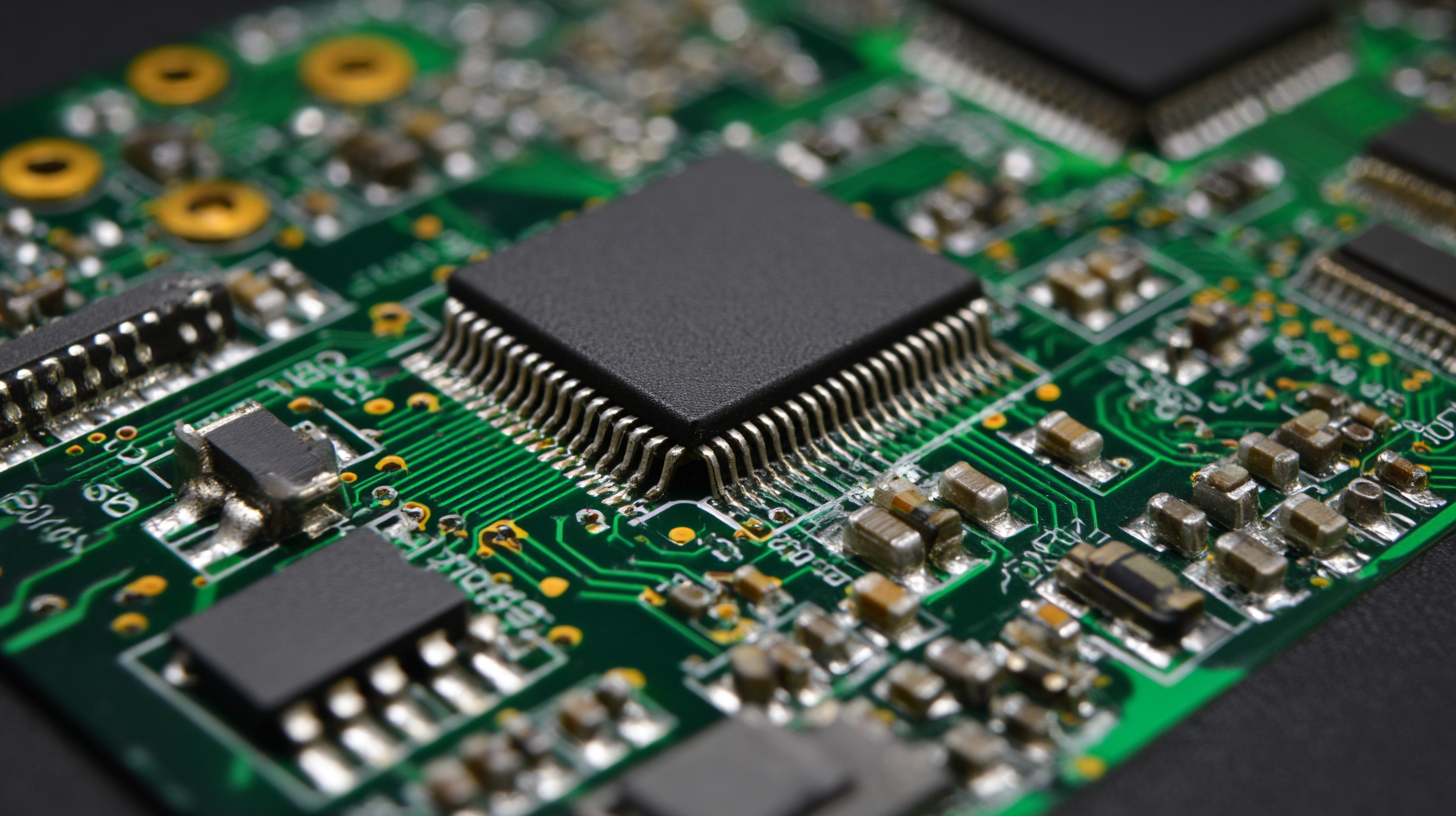

In today's fast-paced technological landscape, the demand for innovative solutions continues to drive the evolution of electronic components, particularly the flexible printed circuit board (FPCB). These remarkable creations offer unparalleled advantages in terms of design flexibility, lightweight structures, and space-saving capabilities, making them an essential choice for a multitude of applications across various industries.

As we delve into the ultimate guide to choosing the best flexible printed circuit board for your project, we will explore the significant aspects that set world-class manufacturing apart, emphasizing China's pride in producing top-tier FPCBs that are exported globally. With an in-depth understanding of the essential factors to consider, from material selection to manufacturing techniques, this guide aims to empower you in making informed decisions for optimal performance and reliability in your electronic designs.

As we delve into the ultimate guide to choosing the best flexible printed circuit board for your project, we will explore the significant aspects that set world-class manufacturing apart, emphasizing China's pride in producing top-tier FPCBs that are exported globally. With an in-depth understanding of the essential factors to consider, from material selection to manufacturing techniques, this guide aims to empower you in making informed decisions for optimal performance and reliability in your electronic designs.

Understanding the Importance of Flexible Printed Circuit Boards in Modern Electronics

Flexible Printed Circuit Boards (FPCs) are becoming increasingly significant in the realm of modern electronics, particularly in the burgeoning sector of electric vehicles. A recent study highlights that major market players have begun to deploy FPC technology in the Pack phase of lithium battery systems. This advancement reflects a growing trend, as FPCs offer both design flexibility and lightweight characteristics, essential for achieving efficient energy management and compact system integration in electric vehicles.

The rapid adoption of FPCs is not surprising, considering that the domestic battery industry has been advancing towards high-performance solutions. Reports from 2018 indicate a significant shift in manufacturing practices among top-tier battery producers, with FPCs being utilized in mass production. This trend suggests that FPCs will play a pivotal role in enhancing the performance and reliability of power sources in electric vehicles, thus driving innovation in this competitive market. As the demand for electric vehicles surges, the integration of flexible circuits is expected to further evolve technology development and application in this crucial industry.

Key Factors to Consider When Choosing a Flexible PCB Manufacturer

When selecting a flexible printed circuit board (FPCB) manufacturer for your project, several key factors should be taken into account to ensure optimal performance and reliability. The FPCB market is anticipated to grow from $5.78 billion in 2024 to $9.75 billion by 2033, highlighting the increasing demand and relevance of these components across various industries.

One vital consideration is the manufacturer's experience in handling complex designs. With rigid-flex PCBs presenting challenges such as high manufacturing complexity and costs, choosing a company that specializes in these intricate processes can make a significant difference. Additionally, understanding the manufacturer’s capabilities in utilizing advanced technologies, including AI-driven techniques in both design and manufacturing, can enhance efficiency and product quality.

Tips: Always request samples and case studies from potential manufacturers to evaluate their expertise and quality standards effectively. Furthermore, consider their supply chain reliability and customer support services, as these factors can greatly influence your project's success.

Comparative Analysis of Top Flexible PCB Manufacturers in the Market

Choosing the right flexible printed circuit board (FPCB) for your project requires a deep understanding of the market landscape. The FPCB market is expected to experience significant growth, with increasing applications in automotive, consumer electronics, telecommunications, and healthcare. As flexibility demands rise in various industries, manufacturers are focusing on a range of products, from rigid-flex boards to multilayer and HDI circuits. The anticipated increase in market size, approximately projected from $874.5 million in 2025 to over $1.36 billion by 2033, underscores the urgency for industry players to enhance production capabilities and meet evolving technology needs.

When selecting an FPCB manufacturer, consider their expertise in multiple product types. For instance, evaluate their ability to produce single-layer, double-layer, and multilayer boards tailored for specific applications. This can greatly impact both the performance and reliability of your project. Additionally, look for manufacturers that demonstrate a commitment to innovation in materials, such as utilizing advanced copper foil technologies that improve conductivity and reduce weight.

Tip: Always request detailed specifications and samples from potential suppliers to better understand their production quality and capabilities. Engaging in discussions about their R&D efforts can also provide insights into their long-term alignment with emerging technologies and market trends.

Comparative Analysis of Flexible Printed Circuit Board Performance

Evaluating Manufacturer Capabilities: Quality, Reliability, and Technology

When evaluating the capabilities of flexible printed circuit board manufacturers, attention to quality, reliability, and technology is of utmost importance. The global market for X-ray inspection systems, a critical tool in ensuring the quality of printed circuit boards, was valued at approximately $700 million in 2021 and is projected to grow significantly, influenced by advancements in both film-based and digital imaging technologies. These systems play a vital role in industries such as electronics and automotive, where precision and defect detection are crucial.

The integration of artificial intelligence and machine learning into manufacturing processes has been highlighted as a game-changer, enhancing the efficacy of X-ray inspection systems and overall production quality. According to recent reports, the demand for digital imaging methods, particularly computed tomography (CT) and direct X-ray photography, is expected to rise sharply as manufacturers seek to adopt more sophisticated inspection techniques to ensure reliability. Furthermore, government initiatives to foster digital transformation in the manufacturing sector underline the importance of collaborative efforts between manufacturers and technology providers, ensuring that the evolution towards smart manufacturing is both efficient and effective.

Tips for Collaborating with PCB Manufacturers for Optimal Results

When collaborating with PCB manufacturers for your flexible printed circuit board (FPCB) project, effective communication is essential for achieving optimal results. A recent industry report from IPC indicates that collaboration gaps can lead to a staggering 30% increase in production costs due to miscommunications and design revisions. To avoid these pitfalls, it's crucial to provide clear specifications and engage in productive dialogues throughout the design process. Establishing a transparent line of communication early on can not only prevent costly mistakes but can also foster a stronger relationship with your manufacturer.

Furthermore, understanding the capabilities and limitations of your chosen manufacturer can greatly enhance the outcome of your project. According to a 2023 market analysis by Research and Markets, the global FPCB market is expected to reach $25 billion by 2026, driven in part by advancements in manufacturing technology. By selecting a manufacturer that invests in cutting-edge equipment and expertise, you ensure that your project benefits from the latest innovations. Regular updates on production stages and feedback loops can further refine the approach, enabling you to fine-tune designs and meet project deadlines efficiently.